|

"MOX Fuel", Plutonium Utilization for light water reactors

It has been

verified that there is no significant differences in characteristics between MOX

fuel and Uranium fuel and that the safety of reactors can be ensured with MOX

fuel as well as with Uranium fuel on the basis of the experience and various

data obtained. Existing light water reactors for power generating facilities can

be utilized in their current status by replacing part of the uranium fuel in the

reactors with MOX fuel.

Since "plutonium" is used for "thermal reactors

(light water reactors in general)", this scheme is called a "plutonium-Thermal"

project in Japan.

According to the current plan, Japanese electric power

companies will be implementing Plutonium-Thermal utilization with 16 to 18 of

the nuclear reactors operating in Japan.

Responding

to a request of The Federation of Electric Power Companies,

since December 1998, we have been conducting domestic

and international technological studies regarding the

MOX fuel fabrication technology. Simultaneously, we

have also been investigating safety measures and facility

plans.

In April 2005, we

concluded "The Basic Cooperation Agreement for

the Location of MOX Fuel Fabrication Plant" with

Aomori prefecture and Rokkasho village, and a license

application for MOX fuel fabrication business was submitted

to the government authorities. Safety assessment is

now in progress.

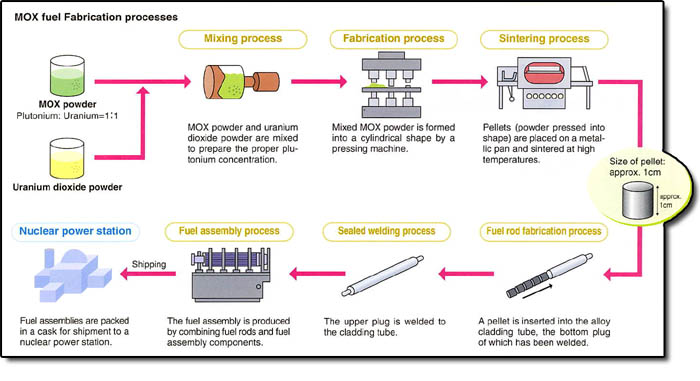

The following is

the outline of the planned MOX Fuel Fabrication Plant.

| Product |

MOX

fuel assembly for domestic light-water reactors

(BWR and PWR) |

| Maximum

fabrication capacity |

130t-HM*/year |

| Size

of main building |

approx.85m

x 85m, 2 above-ground levels and 3 underground

levels |

| Number

of operating employees |

Nearly

300 |

| Completion |

June,

2015 |

| Construction

cost |

approx.

¥190 billion |

*"t-HM" stands for "tons of

heavy metal" which indicates the weight of plutonium and uranium metallic

content in MOX.

|

Safety

measures at the MOX Fuel Fabrication Plant

At

the MOX fuel Fabrication Plant, where safety

will be given top priority, rigorous critical

safety controls will be implemented. For instance,

the dry process will be adopted for the production

process from MOX powder to fuel assembly. Other

major measures to assure safety are as follows:

- "Mass control" to keep

nuclear fuel substances within the specified

level

- "Shape/dimension control"

to keep the containers for MOX fuel in the

specified shape and dimensions

- "Neutron absorbent control"

to remove fissionable neutrons by the use

of boron, which absorbs neutrons

These measures will be appropriately

combined to realize the highest possible safety

level. In addition, we will introduce the same

safety measures as those already implemented in

other businesses. |

|